Temperature can change everything. It can turn water from ice to steam or soften steel. To understand materials’ operando behavior at high temperatures, you have to test their performance at temperature. This is challenging at small scales due to thermal gradients and thermal expansion.

FemtoTools systems meet these challenges using precision MEMS heating to achieve rapid temperature matching and thermal control. This provides stable measurements at temperatures up to 800 °C, as shown in situ in the SEM.

This critical application enables access to a wide range of high-temperature materials phenomena: phase transformations, brittle-ductile transitions, creep, embrittlement, and much more.

Application Examples

- 01 Micropillar Compression

- 02 Micro-Tension of Silver

- 03 Micro-Shear of Silicon

High-Temperature In-Situ SEM Micro-Compression Testing

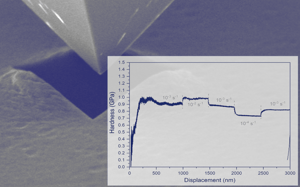

Micro-compression is an attractive, relatively simple geometry, as it provides a direct uniaxial measurement of strength. Performing these tests at operando temperatures allows materials’ mechanical behavior to be ascertained with confidence at service conditions.

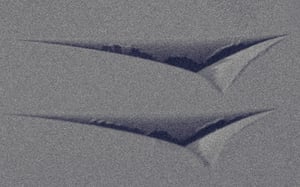

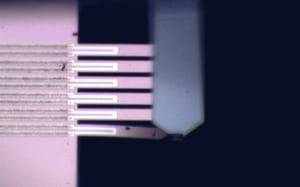

In this example, lithographically-manufactured pillars of Silicon are compressed at high temperatures to study their brittle-ductile transition. As shown in the in-situ SEM videos, at temperatures above 200° C, significant amounts of plasticity are observed in ‘brittle’ Silicon pillars!

High-Temperature Micro-Tension of Silver

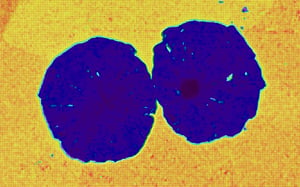

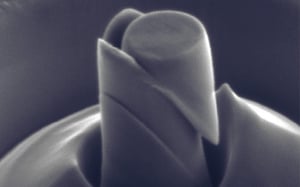

Tension testing is the gold standard for determining materials’ ductility, a key parameter for mechanical performance. Micro-scale tension testing is especially challenging due to requirements of the relatively complex specimen geometry and of native displacement control to prevent overloading during a intermittent plastic flow of dislocations.

In this example, the Mortensen group at EPFL met both of these challenges by using micro-casting to produce numerous samples and FemtoTools high temperature module. This enabled them to study the tensile behavior and intermittent plasticity as a function of temperature. Find out more in their article in Acta Materialia 249 (2023) 118817.

High-Temperature Micro-Shear of Silicon

Is Silicon is a brittle material? Not always. Temperature can change everything.

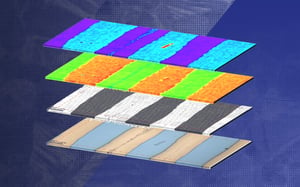

At elevated temperatures, Silicon undergoes brittle-ductile transitions as dislocation mechanisms and velocities change. However, these transitions depend on the type of loading, i.e. tension, compression, or shear.

In this example, acquired in collaboration with the Laboratory for Nanometallurgy at ETH Zurich, [110]-oriented Silicon is sheared directly on its primary slip planes at 600 °C. Color strain maps are provided using digital image correlation (DIC) using the speckle patterns and in-situ imaging at temperature in the SEM. This enables direct measurement of the local strains within the shear zones.

Application Notes

In-Situ, High Temperature Microcompression of Silicon

Nanoindentation

READ MORE ->

Read More

Mechanical Microscopy

READ MORE ->

Read More

Correlative Mechanical Microscopy

READ MORE ->

Read More

Strain-Rate Control

READ MORE ->

Read More

Scratch Testing

READ MORE ->

Read More

Soft Materials Testing

READ MORE ->

Read More

MEMS Mechanical Testing

READ MORE ->

Read More

Micro-Pillar Compression

READ MORE ->

Read More