A core theme of materials science is the relationship between microstructure and mechanical properties. Mechanical microscopy provides a powerful new method to simultaneously measure microstructure and mechanical properties.

Analytical techniques such as EDX (Energy-Dispersive X-ray spectroscopy) and EBSD (Electron Backscatter Diffraction) allow for the characterization of local composition, as well as crystal structure and orientation information. The combination of these techniques with nanoindentation mapping offers new insights into the relationships between structure, composition, and mechanical properties of materials, through what we call Correlative Mechanical Microscopy.

Application Examples

- 01 Grain Anisotropy

- 02 Phase Deconvolution

- 03 “Out of this World” Correlations!

- 04 Understanding AM Processess

- 05 Surface Treatments

Grain Anisotropy

Polycrystalline materials like metal and ceramics are composed of tiny crystalline grains whose properties often vary with their orientation, i.e. grain anisotropy. Correlated Mechanical Microscopy using EBSD is the ideal tool for understanding the influence of this on local mechanical properties!

In this example, commercial pure Titanium demonstrates an extremely high level of anisotropy, where neighboring grains have mechanical properties varying by more than a factor of 2! This demonstrates its high strengthening potential using forging techniques to achieve strength through crystallographic texture.

| Nanoindentation & EBSD Correlative techniques |

Combinatorial Phase Deconvolution

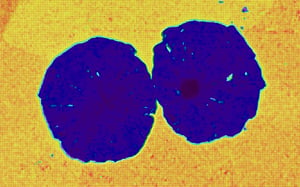

Extracting phase-level properties out of different materials which have very similar or overlapping properties can be very challenging. Statistical and clustering methods will often assume them to be a single phase. Correlative Mechanical Microscopy with EDX solves this issue.

In this example, a Ni-Ta diffusion couple is used as a combinatorial library to investigate a wide range of Ni-Ta alloy compositions and intermetallic phases. Several of these phases have overlapping properties, but distinct compositional ranges. By using correlative EDX with nanoindentation mapping, all phases are easily identified. Read more at Small Methods 6 (2022) 2101084.

| Nanoindentation & EBSD Correlative techniques |

“Out of this World” Correlations!

Meteorites literally have extraterrestrial microstructures: They are from out of this world! These form through extreme shocks and extremely slow cooling rates. To better understand these complex materials, Correlated Mechanical Microscopy is an essential tool to determine their structure-composition-mechanical properties relationships.

In this example, a fragment of the Seymchan meteorite recovered in remote Siberia is probed to examine the various phases and compositional gradients contained within. Correlated Mechanical Microscopy easily reveals the various phase’s compositions and crystallographic structures and orientations.

| Nanoindentation & EDX & EBSD Correlative techniques |

Understanding Additive Manufacturing Microstructures

Additive Manufacturing methods are transforming modern manufacturing by enabling easy fabrication of complex 3D part geometries with novel microstructures. Understanding the relationships between these microstructures and mechanical performance is greatly facilitated using Correlative Mechanical Microscopy.

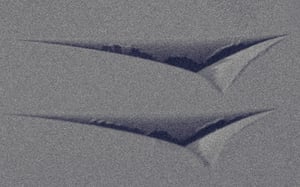

In this example, the “fish-scale” microstructure of 316L stainless steel additively manufactured using laser powder bed fusion (L-PBF) is revealed in terms of both its mechanical properties and the corresponding grain orientation relationships.

| Nanoindentation & EBSD Correlative Techniques |

Surface Treatments

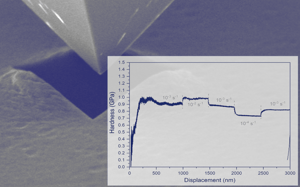

Nitriding is a common surface treatment for hardening the surface of steels. Nitrogen can act as a hardening agent in steels similar to carbon, but with less loss in ductility. Correlated Mechanical Microscopy can identify the effective depth of a nitriding process, as well as the evolution of different nitride phases.

In this example, a 31CroMoV9 steel (1.8519) edge-hardened by gas nitriding was investigated. Microstructural trends in the maps correlate well with metallography and EDX nitrogen concentration measurements. Mechanical microscopy successfully revealed the presence of both phases within the surface white layer of the gas-nitrided steel as well as the gradient in mechanical properties between the nitrided surface and ferrite substrate.

| Nanoindentation & EBSD Correlative Techniques |

Nanoindentation

READ MORE ->

Read More

Mechanical Microscopy

READ MORE ->

Read More

Strain-Rate Control

READ MORE ->

Read More

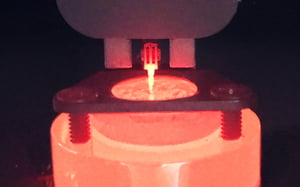

High-Temperature Testing

READ MORE ->

Read More

Scratch Testing

READ MORE ->

Read More

Soft Materials Testing

READ MORE ->

Read More

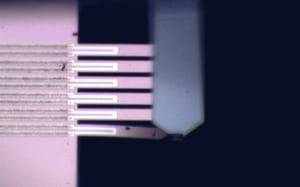

MEMS Mechanical Testing

READ MORE ->

Read More

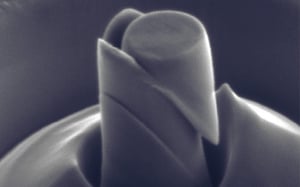

Micro-Pillar Compression

READ MORE ->

Read More